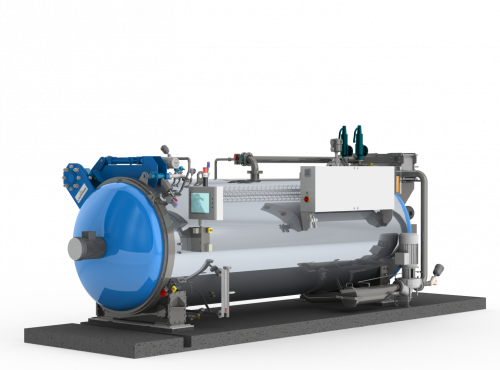

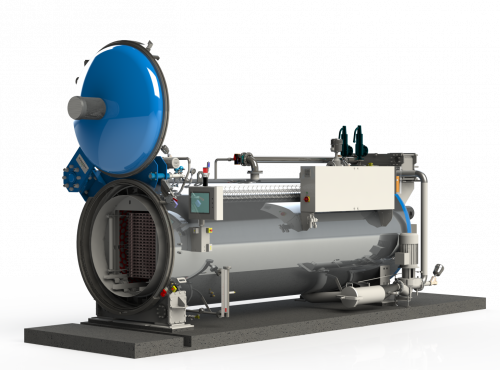

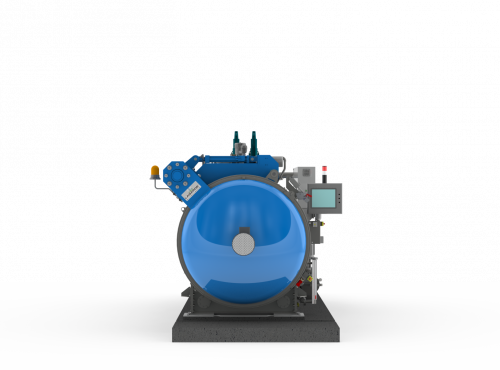

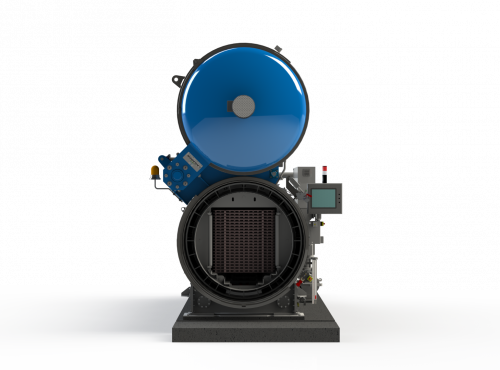

GREEN ONE - LAGARDE® ROTARY RETORT

GREEN ONE - ROTARY RETORT

by LAGARDE AUTOCLAVES

STEAM/AIR

Designed, produced in FRANCE,

An autoclave powerful and complete, because your production is our priority.

by LAGARDE AUTOCLAVES

STEAM/AIR

Designed, produced in FRANCE,

An autoclave powerful and complete, because your production is our priority.

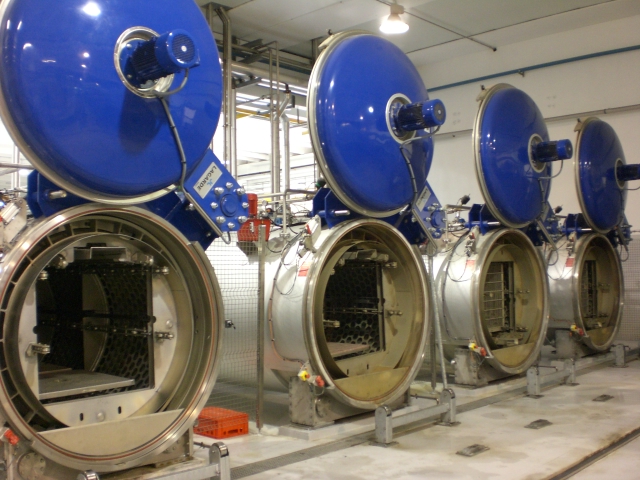

Specialized in horizontal retort manufacturing, LAGARDE Autoclaves®, part of the SCHOLZ group, is among the world leaders in batch thermal processing and the inventor of the Steam & Air process, Patent N° FR 2225702 published in 1974 which ensures a considerable reduction in energy consumption (steam, water, electricity) resulting in a very low unit cost of production (warranted by calculation and experience) compared with sterilisation process such as Full Water Immersion.

Lagarde manufactures in 1975 its first rotary retort.

Lagarde produces tailor-made autoclaves for all its customers and also offers a standard range.

For more information visit the website of LAGARDE Autoclaves : https://www.lagarde-autoclaves.com/en/home/